DISINFECTION AND WATER RECYCLING PLANTS.

Clariflocculation.

The term clariflocculation means the processes sum of coagulation, flocculation and sedimentation combined to obtain as principal objective the destabilization of a colloidal suspension and removal of the aggregates that are formed.

The clariflocculation together the effect of reduction of turbidity, allows to obtain a number of other important results, such as:

- Total Suspended Solids reduction (50 - 80%)

- Bacteria, viruses, and parasites concentration reduction (over 90% reduction of coliform);

- Inorganic micropolluting reduction (40 - 85% heavy metals reduction);

- Efficiency improvement filtration process;

- Residual organic fraction reduction (60 - 75% of BOD5)

- The possibility to realize simultaneously the phosphorous precipitation.

The coagulating agents most commonly used are the salts of iron and aluminum possibly in combination with anionic polyelectrolytes. Using aluminum chloride operating at pH levels below 6.5 and this avoids the use of lime while maintaining the low sludge production.

The doses used are of the order of some tens of mg/l for the coagulants metal and of a few tenths of mg/l for the polyelectrolytes.

The choice and dosage of coagulant and the conditioning is performed by performing tests of Jar Test checking in particular the influence of pH, especially if you make the precipitation with lime.

The efficiency of the process also depends on the speed with which the reagents are mixed, by the stability of the flakes and by their sedimentation.

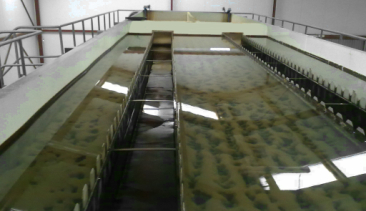

CLARIFLOCCULATION SYSTEMS

Filtration.

Filtration, together with the disinfection, represents one of the processes which makes more use.

Filtration can be carried out as an alternative or downstream of the secondary sedimentation or, as often happens, combined with the clariflocculation (filter-flocculation).

The filtration also improves the efficiency of the disinfection in the case of UV the filtration is necessary to increase the transparency and allow the penetration of the radiation, while, in the case of the chlorination and treatment with ozone, the filtration reduces the concentration of the organic allowing the use of lower dosages and contact times.

The different types of filtration are distinguished based on the type of material used and the procedures for feeding and washing:

- Single, dual, multi-media down flow

- Deep-bed down-up flow single medium

- Pulsed bed mono-medium flow down

- Shallow-bed mono, dual flow down to the bridge

- Cleaning up continuous-flow mono medium

The filtration speed is between 6 and 12 m / h, the maximum limit of 12 m / h is set to ensure a strict standard microbiological (2.2 FC/100 mL.)

Micro-organisms size is between 0.5 and 3 microns while the limit of particle size is

3-5 microns for which filtering beds are capable of removing agglomerates of microorganisms.

For this reason, if it intends to pursue the maximum efficiency of

removal of suspended solids, it is necessary recourse to filter-flocculation.

ANTRACITE, SAND AND GRAVEL FILTRATION.

Cloration.